5s Methodology What Is 5s Methodology 5s Methodology Explanation Simplilearn

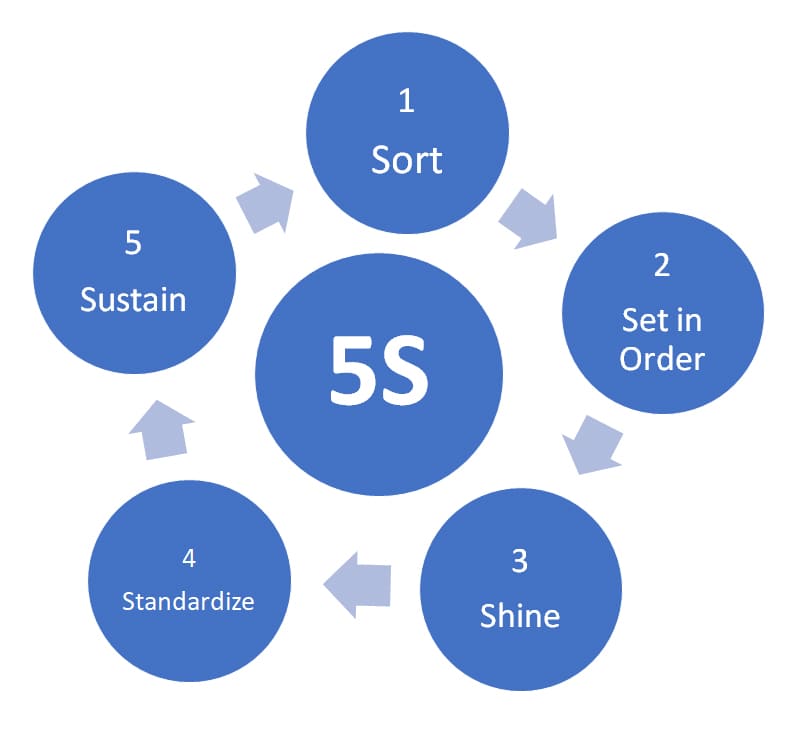

5s Methodology What Is 5s Methodology 5s Methodology Explanat 🔥green belt certification training course: simplilearn quality management lean six sigma green belt training?utm campaign=sixsigma ukhgd3ubx. This presentation on 5s methodology will take you through everything you need to know about the workplace organization method, 5s. this video also covers a number of different topics like the basics of the 5s methodology, its benefits and the process of 5s, like sort, set in order, shine, standardize, and sustain. so now, let's jump in and learn about the 5s methodology. learn to develop your.

5s Methodology What Is 5s Methodology 5s Methodology Explanat 5s. the big idea. 5s is a five step methodology that, when followed, creates a more organized and productive workspace. in english, the 5s’s are: sort, straighten, shine, standardize, and sustain. 5s serves as a foundation for deploying more advanced lean production tools and processes. The 5s method is often used as the basis for kaizen. by implementing the principles of 5s (sort, systematize, clean, standardize, self discipline), companies lay the foundation for an organized, clean and efficient work environment. this improved foundation then makes it easier to integrate kaizen principles into daily operations. What is 5s. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. improved visual controls are implemented as part of 5s to make any process non conformance’s obvious and easily detectable. 5s is often one element of a larger lean initiative and promotes. 5s is a methodology for creating an organized and productive workspace by sorting, straightening, shining, standardizing, and sustaining. using 5s as a foundation, advanced processes and tools to implement lean production can be developed. 5s is the perfect tool to identify the first improvement projects in your company to eliminate waste.

What Is 5s Methodology 5s Quality System 5s Workplace Methodology What is 5s. the 5s method is a standardized process that when properly implemented creates and maintains an organized, safe, clean and efficient workplace. improved visual controls are implemented as part of 5s to make any process non conformance’s obvious and easily detectable. 5s is often one element of a larger lean initiative and promotes. 5s is a methodology for creating an organized and productive workspace by sorting, straightening, shining, standardizing, and sustaining. using 5s as a foundation, advanced processes and tools to implement lean production can be developed. 5s is the perfect tool to identify the first improvement projects in your company to eliminate waste. Improved safety. higher equipment availability. lower defect rates. reduced costs. increased production agility and flexibility. improved employee morale. better asset utilization. enhanced enterprise image to customers, suppliers, employees, and management. five s (5s) example: workplace scan diagnostic checklist. The 5s methodology is an organization system for workplaces used in manufacturing and other industries for decades to improve efficiency, reduce waste, and increase safety. it is also considered one foundational pillar of having a lean company. the 5s’s stand for the procedures that include sort, set in order, shine, standardize, and sustain.

5s Methodology What Is 5s Methodology 5s Methodology Explanat Improved safety. higher equipment availability. lower defect rates. reduced costs. increased production agility and flexibility. improved employee morale. better asset utilization. enhanced enterprise image to customers, suppliers, employees, and management. five s (5s) example: workplace scan diagnostic checklist. The 5s methodology is an organization system for workplaces used in manufacturing and other industries for decades to improve efficiency, reduce waste, and increase safety. it is also considered one foundational pillar of having a lean company. the 5s’s stand for the procedures that include sort, set in order, shine, standardize, and sustain.

What Is 5s Methodology Example And Implementation Parsadi

Comments are closed.