Dd15 Cooling System Diagram

Dd15 Coolant System Diagram Issues And Maintenance Tips The cooling system is an essential component of a dd15 engine, designed to regulate the temperature and prevent the overheating of various engine parts. understanding the cooling system diagram is crucial for efficient maintenance and troubleshooting of the engine. the cooling system relies on a series of interconnected components and processes. 2 description and operation of the dd15 and dd16 exhaust gas recirculation cooler. the primary purpose of the exhaust gas recirculation (egr) cooler is to cool the engine exhaust gases prior to entering the intake manifold. exhaust gas cooling is accomplished by the flow of exhaust gases through the egr cooler tubes.

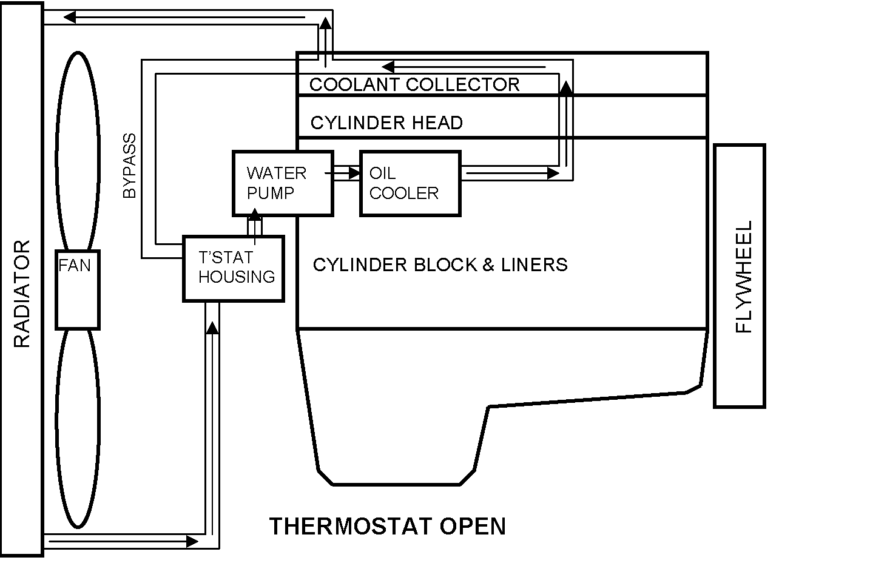

Cooling System Detroit Diesel Troubleshooting Diagram Vrogue Co Detroit™ gen 5 heavy duty dd15 major engine components are shown below: water pump. oil coolant module. oil filter. high pressure fuel rail. air intake manifold. hydrocarbon fuel doser block. high pressure fuel pump. air compressor. If yes, change the cooler. refer to “5.1 exhaust gas recirculation (egr) cooler” in the “engine” chapter of the epa07 dd15 workshop manual (ddc svc man 0002). if no, troubleshoot for other internal coolant system leaks. check for coolant out exhaust from an exhaust port and check for internal engine damage. Epa07 10 dd platform workshop manual engine 28.1 description and operation of cooling system and related components a schematic of the cooling system in the following illustration shows the coolant flow to the engine components. 1. coolant pump 10. fan 19. heat exchanger m. engine 2. oil cooler 11. radiator 20. doser r. auto trans cooler flow 3. Detroit diesel dd15 is a 14.8 liter, 6 cylinder engine that can produce 455 to 560 horsepower, depending on the configuration. this engine may meet the epa 07 environmental requirement for the united states with its integrated egr system, and the epa 10 regulations can be met by fitting the engine with an adble (scr) barrel.

The Ultimate Guide To Understanding The Dd15 Cooling System Diagrams Epa07 10 dd platform workshop manual engine 28.1 description and operation of cooling system and related components a schematic of the cooling system in the following illustration shows the coolant flow to the engine components. 1. coolant pump 10. fan 19. heat exchanger m. engine 2. oil cooler 11. radiator 20. doser r. auto trans cooler flow 3. Detroit diesel dd15 is a 14.8 liter, 6 cylinder engine that can produce 455 to 560 horsepower, depending on the configuration. this engine may meet the epa 07 environmental requirement for the united states with its integrated egr system, and the epa 10 regulations can be met by fitting the engine with an adble (scr) barrel. The dd15 coolant hose diagram is a visual representation of the coolant system in the dd15 engine, a heavy duty engine commonly used in commercial trucks. the coolant system is responsible for keeping the engine cool and preventing it from overheating. a properly functioning coolant system is crucial for the engine’s performance and longevity. Mbe 900 4000 pid 110 – coolant temperature above recommended normal operating range; mbe 900 4000 pid 105 troubleshooting; mbe 900 4000 pid 111 – coolant outside normal operating range; categories. air intake system; cooling system; dd15; dd15 operator guide; ddec iii iv single ecm; ddec multi ecm; electrical; engine; engine; engine not to.

Comments are closed.