Floor Jack Overload Valve Adjustment Floor Jack

How To Adjust A Hydraulic Floor Jack Viewfloor Co Adjusting the overload valve is a relatively simple process. the first step is to check the jack’s rating plate to make sure that the valve is set to the correct setting. the setting should match the maximum weight rating of the jack. once the correct setting is determined, the valve can be adjusted using a screwdriver. The floor jack still slowly lowered after adding oil, so the next step is to check the release valves. i disassembled the jack, drained the oil, and cleaned.

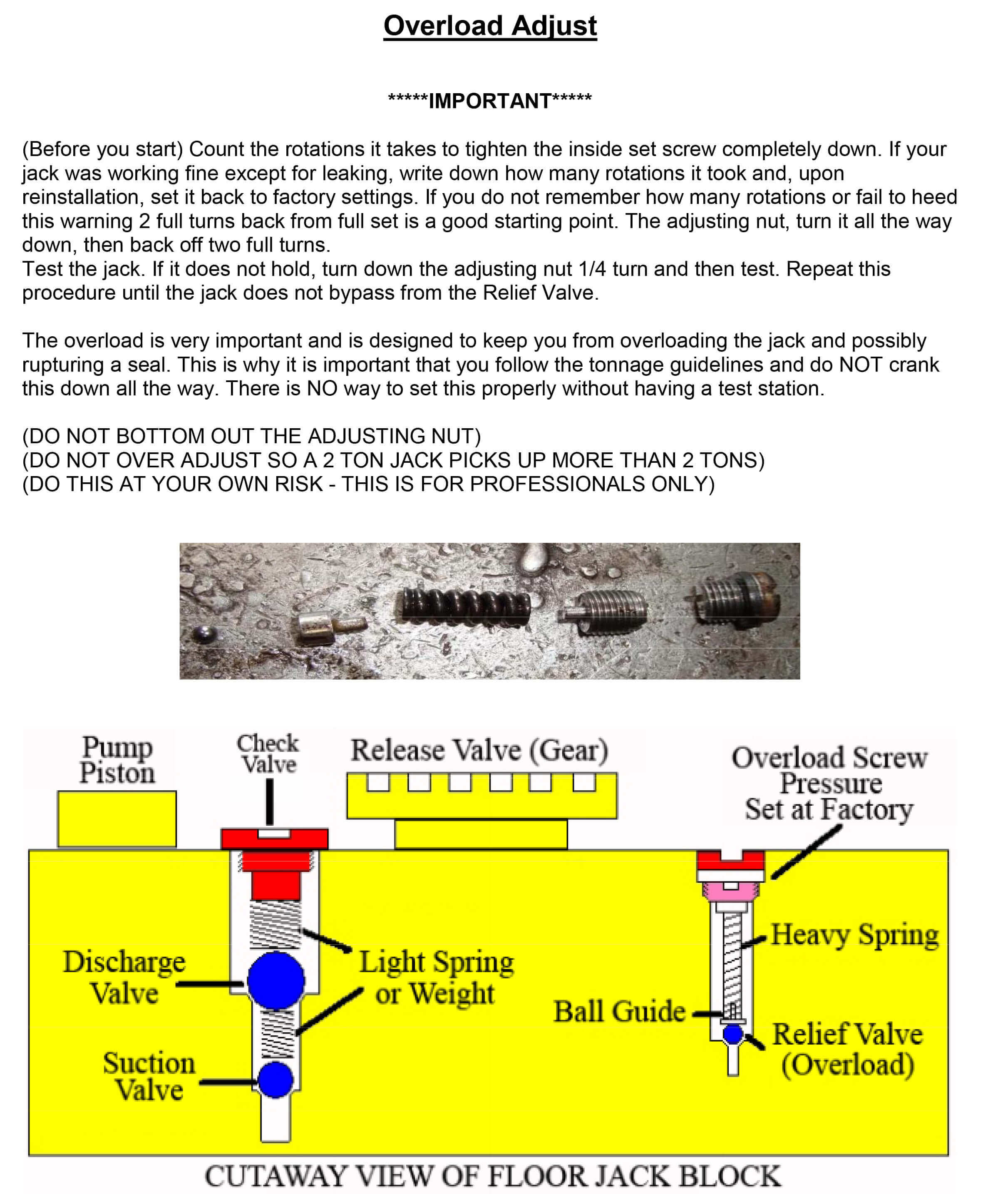

How To Instructions Resources Lazzar S Floor Jack Hydraulic The flare angle needs to be slightly straightened to allow the seal to be pushed into the cylinder. install it on the end of the ram with the flare pointing away from the ram. next, place a towel rag on a work bench and soak a six inch circle in the center with hydraulic fluid. this will become your work area for “working” the flare of the. Ensure you’re not overloading the floor jack. all floor jacks have a weight limit it can’t and shouldn’t exceed. in addition, most manufacturers install a safety overload valve that prevents the floor jack from working when overloaded. for instance, a pittsburgh 3 tone floor jack can’t lift more than three tons of weight. Step 5: test the jack. once the release valve has been replaced and reattached, it is important to test the jack to make sure it is functioning properly. to do this, raise the jack to its highest level and then release the handle. the jack should lower slowly and evenly. Most floor jacks are fitted with a safety overload valve. this feature works to prevent the jack from working when overloaded. typically, a pittsburgh 3 ton floor jack won’t lift more than three tons even if you tried. the rule of thumb applies. the law states that a floor jack should be rated at least three quarters of your vehicle’s gross.

How Do You Adjust Hydraulic Floor Jacks Viewfloor Co Step 5: test the jack. once the release valve has been replaced and reattached, it is important to test the jack to make sure it is functioning properly. to do this, raise the jack to its highest level and then release the handle. the jack should lower slowly and evenly. Most floor jacks are fitted with a safety overload valve. this feature works to prevent the jack from working when overloaded. typically, a pittsburgh 3 ton floor jack won’t lift more than three tons even if you tried. the rule of thumb applies. the law states that a floor jack should be rated at least three quarters of your vehicle’s gross. It's hard to be without your floor jack. we show you how to fix and rebuild your floor jack, or just about any other type of jack. most floor jacks have a si. Release air that might be trapped in the jack’s hydraulics. this is one of the more common problems that catches people by surprise. air can sometimes get trapped in the jack and prevent it from working properly. thankfully, this is an easy floor jack repair to perform – just remove the screw of the oil filler and place the jack’s release.

Comments are closed.