How To Create A Tube Flare

Make A Flare Connection Fine Homebuilding This clip provides an in depth look at the flaring process and addresses proper technique, tools and what to look for in a good flare. to view the full chapt. If it doesn’t say it’s annealed, it probably isn’t. the first step is cutting the tubing. standard tubing cutters lead a thin burr on the inside of the tubing that must be removed to achieve a good flare. we will run through the process of making a 45 degree flare on a 5 16 inch length of tubing.

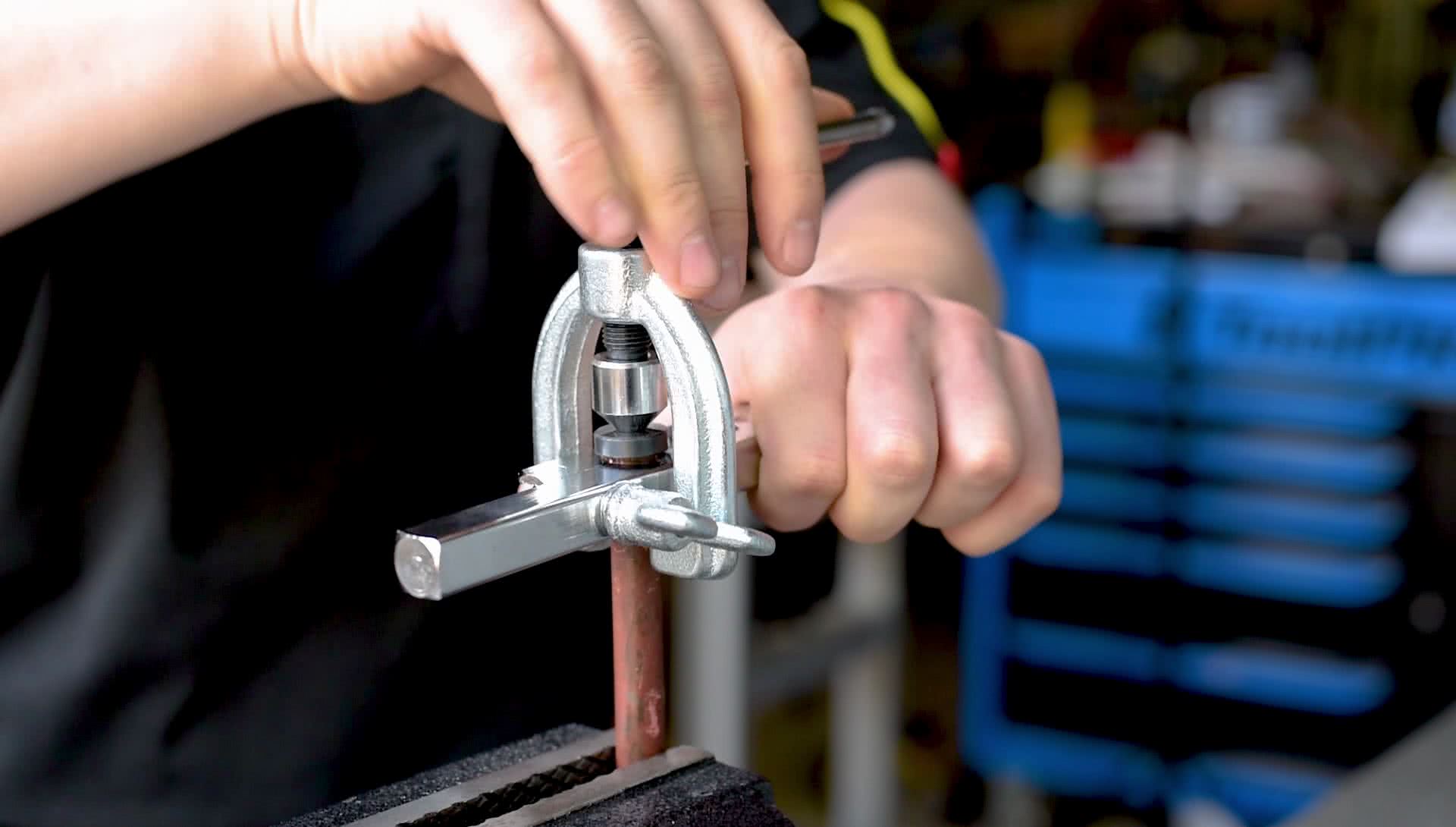

How To Create A Tube Flare Place the copper tubing into the flare form. make sure the tubing you use has the correct diameter and leave about 1 16" of tubing hanging out. time to secure the nuts. tighten the nearest nut manually before tightening the far nut to ensure that the block grips the tube tightly enough. make the yoke fit the flare block. Have you ever wondered how to flare copper pipe? or perhaps you've heard the term used around trade school or the jobsite, but never quite knew what it was . Flaring the tube. place the flaring nut over the end of the tube. center the flaring cone over the tubing. tighten the flaring tool to lower the press into the tubing until it forms a flare. do not over tighten, which risks splitting the copper. loosen and remove the flared tubing. Follow these step by step instructions to effectively flare copper tubing: cutting the tubing: begin by using a tube cutting tool to cut the copper tubing accurately for a clean and precise cut. removing excess copper: after cutting the tubing, ensure that there are no loose pieces of copper at the end of the tubing.

How To Create A Tube Flare Flaring the tube. place the flaring nut over the end of the tube. center the flaring cone over the tubing. tighten the flaring tool to lower the press into the tubing until it forms a flare. do not over tighten, which risks splitting the copper. loosen and remove the flared tubing. Follow these step by step instructions to effectively flare copper tubing: cutting the tubing: begin by using a tube cutting tool to cut the copper tubing accurately for a clean and precise cut. removing excess copper: after cutting the tubing, ensure that there are no loose pieces of copper at the end of the tubing. Step one: measure the tubing so you can reach the back of the female socket of the flange. step two: cut the tube with a tube cutter. step three: use a file or the deburring blade on the tube cutter to ream the inside and outside of the tubing. step four: clean the oxides from the tube and the inside of the socket. In this quick tip, we take a look at how to flare tubing for an fittings. this quick video shows the process of flaring a piece of hard line tubing for 37 d.

How To Create A Tube Flare Step one: measure the tubing so you can reach the back of the female socket of the flange. step two: cut the tube with a tube cutter. step three: use a file or the deburring blade on the tube cutter to ream the inside and outside of the tubing. step four: clean the oxides from the tube and the inside of the socket. In this quick tip, we take a look at how to flare tubing for an fittings. this quick video shows the process of flaring a piece of hard line tubing for 37 d.

How To Create Your Own Flared Tubing Toolpro Tube Flaring Kit

Comments are closed.