Leak Test Procedure For Piping Zanerosgood

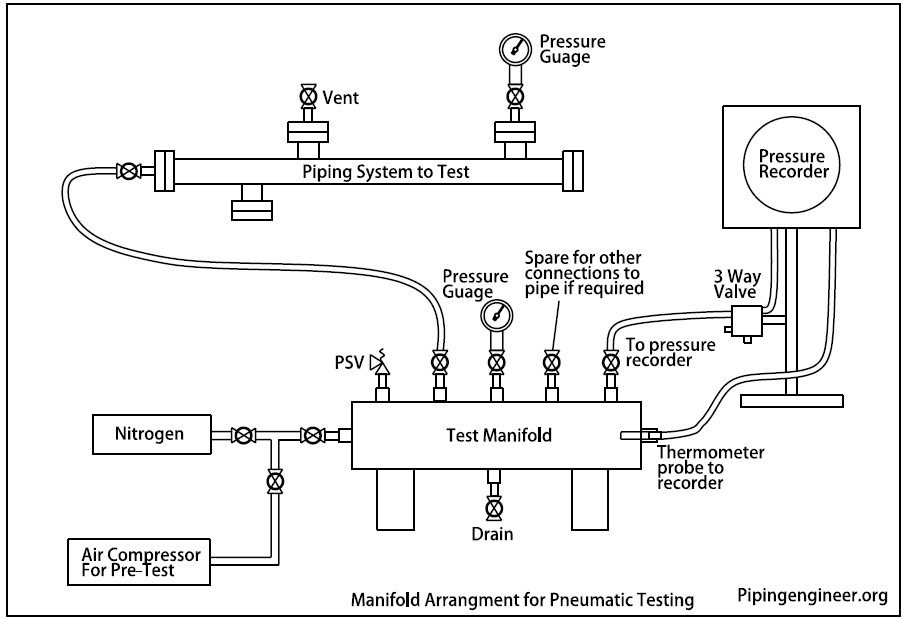

Leak Test Procedure For Piping Zanerosgood Piping examination and leak testing guide b31.8 pipelines april 2017 . process industry practices page 2 of 6 . 1. introduction . scope . this practice describes guidelines for specifying requirements for examination and leak testing of metallic pipeline systems designed in accordance with . asme b31.8 gas transmission and distribution piping. This procedure is applicable to boiler external piping and pressure vessels constructed to asme code b311 sec vii div 1. an annual precision leak detection test. hold the piping under pressure for duration of 2 hours and observe for any leakage or pressure drop if the pressure gauge shows a steady reading after 2 hours.

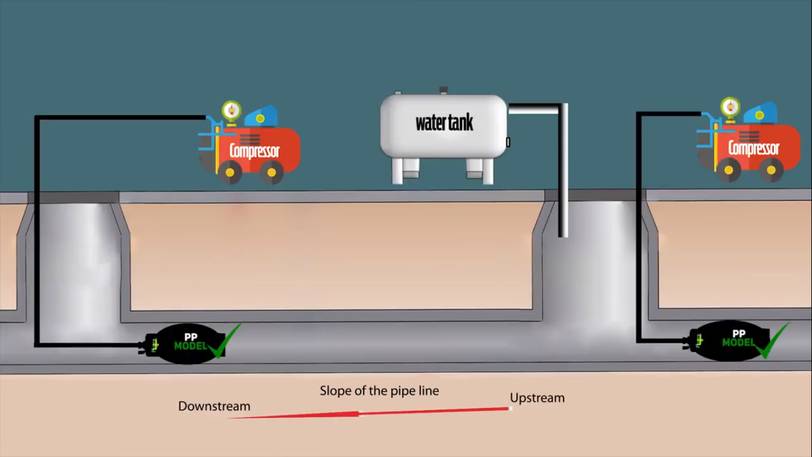

Leak Test Procedure For Piping Zanerosgood A.1 introduction. establishing an in‐house procedure for cleaning and leak testing installed piping sys tems is an essential—not just for the engineering firm designing a facility or for the contractor fabricating and installing the piping systems. this type of procedure is an essential tool for the owner user as well. Note: the test duration of asme b31.3 allows the test pressure to be greater than 1.5x the design pressure whereas other standards have a precaution to limit the test pressure to 1.5x the design pressure. industrial piping best practices rev 2308a page 1 of 2 asahi america, inc. 655 andover street, lawrence, ma 01843 800 343 3618. The design temperature is from –29°c (–20°f) through 186°c (366°f) the initial service leak test is a process by which the test fluid is the fluid that is to be used in the intended piping system at operating pressure and temperature. it is accomplished by connecting to the fluid source with a valved connection and then gradually. Multiply the test pressure by the table 1 multiplier to determine the allowable elevated temperature test pressure. † use the 80°f (27°c) multiplier for 80°f (27°c) and lower temperatures. ‡ the maximum service temperature for performance pipe pe pressure piping is 140°f (60°c).

Construction Leak Test Procedure Pdf Leak Pipe Fluid Conveyance The design temperature is from –29°c (–20°f) through 186°c (366°f) the initial service leak test is a process by which the test fluid is the fluid that is to be used in the intended piping system at operating pressure and temperature. it is accomplished by connecting to the fluid source with a valved connection and then gradually. Multiply the test pressure by the table 1 multiplier to determine the allowable elevated temperature test pressure. † use the 80°f (27°c) multiplier for 80°f (27°c) and lower temperatures. ‡ the maximum service temperature for performance pipe pe pressure piping is 140°f (60°c). When the piping is leak tested at pressures above the design pressure, the test also demonstrates that the piping is strong enough to withstand the pressure. for large bore piping where the pipe wall thickness is close to the minimum required by the code, being strong enough to withstand the pressure is an important test. 1. required leak test. before initiating piping testing according to asme b31.3, there are considerations and options outlined to ensure the integrity of the piping system. the primary testing method recommended is a hydrostatic leak test, as per para. 345.4. however, the owner has flexibility in certain situations.

Leak Test As Per En1610 Plugco Plugco Net When the piping is leak tested at pressures above the design pressure, the test also demonstrates that the piping is strong enough to withstand the pressure. for large bore piping where the pipe wall thickness is close to the minimum required by the code, being strong enough to withstand the pressure is an important test. 1. required leak test. before initiating piping testing according to asme b31.3, there are considerations and options outlined to ensure the integrity of the piping system. the primary testing method recommended is a hydrostatic leak test, as per para. 345.4. however, the owner has flexibility in certain situations.

Comments are closed.