Leveraging Advanced Water Filtration To Maximize Cooling Tower Performance

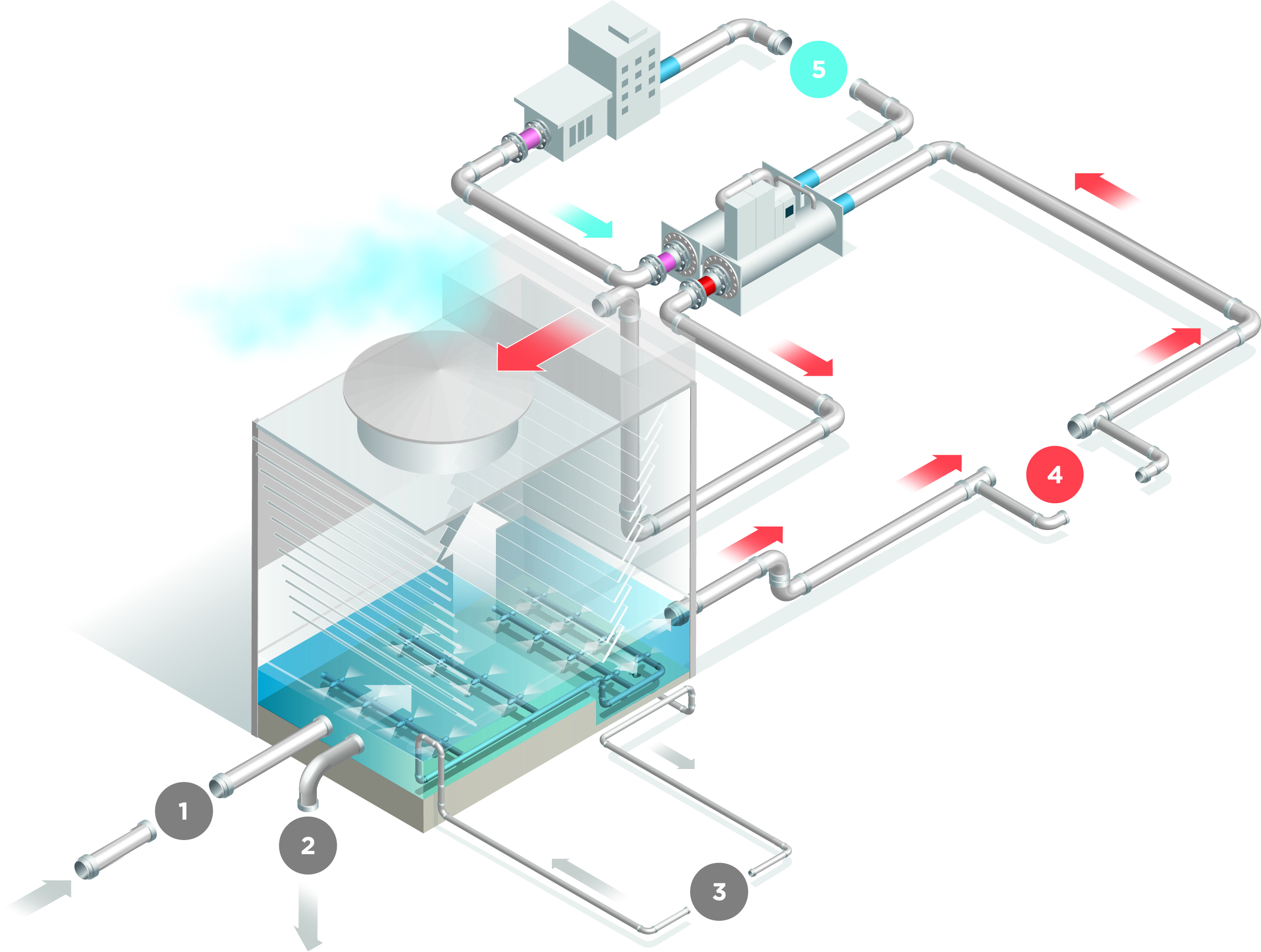

Leveraging Advanced Water Filtration To Maximize Cooling Tower Performance Protecting expensive cooling tower assets will decrease the need for chiller maintenance and repairs or the need for replacement altogether. advanced water filtration is more efficient compared to traditional methods of cleaning a cooling tower (i.e. draining the tower and shoveling sediment from the sump which has significant costs in downtime. In the realm of cooling tower efficiency, wahaso’s innovative solutions offer a technologically advanced and environmentally conscious approach to water conservation. conclusion: by leveraging the capabilities of the ct recover system, building owners, facility engineers, and maintenance staff can optimize performance, minimize water waste.

Leveraging Advanced Water Filtration To Maximize Cooling Tower Performance Guaranteeing water quality within cooling tower systems is vital to achieve maximum performance and extended lifespan, and proper filtration plays a crucial role in achieving this goal. filtration systems effectively remove impurities, sediment, and contaminants from the water, preventing them from accumulating in the cooling tower and causing. This guide outlines key strategies for optimizing cooling tower performance through effective water treatment. understanding the risks of inadequate water treatment. inadequate water treatment in cooling towers can lead to several significant issues that should concern every facility manager and engineer. it is important to understand what to. A side stream filtration system’s flow rate generally ranges from 3 to 10% (but can be up to 20%) of the total recirculated cooling water flow rate. a side stream filtration percentage of 3% or less of the total circulation flow rate has been shown to damage cooling systems, causing fouling throughout the cooling loop. Calculation: for a cooling tower with a water volume of 100,000 gallons: overdosing (traditional): 100,000 gallons x 12 ppm = 1,200 pounds of chemicals. optimal dosing (with lakewood 3175): 100,000 gallons x 10 ppm = 1,000 pounds of chemicals. this equates to a 16.7% reduction in chemical usage, lowering operational costs and minimizing.

Leveraging Advanced Water Filtration To Maximize Cooling Tower Performance A side stream filtration system’s flow rate generally ranges from 3 to 10% (but can be up to 20%) of the total recirculated cooling water flow rate. a side stream filtration percentage of 3% or less of the total circulation flow rate has been shown to damage cooling systems, causing fouling throughout the cooling loop. Calculation: for a cooling tower with a water volume of 100,000 gallons: overdosing (traditional): 100,000 gallons x 12 ppm = 1,200 pounds of chemicals. optimal dosing (with lakewood 3175): 100,000 gallons x 10 ppm = 1,000 pounds of chemicals. this equates to a 16.7% reduction in chemical usage, lowering operational costs and minimizing. Lakos cooling tower filtration units have several benefits that transform the filtration landscape and help reduce the risk of corrosion, microbiological growth, and scale. some of these benefits include: reduces under deposit corrosion, eliminates the nourishment for biological growth, and prolongs the basin's lifespan. A comprehensive inspection and cleaning are vital before starting a cooling tower, especially after a downtime. it's crucial to check for debris, sediment, and any signs of microbial growth, such as legionella, which thrives in stagnant water. systems that have been inactive, particularly during warmer months, are at higher risk for developing.

How To Improve Filtration Effectiveness In Cooling Towers Galebreaker Lakos cooling tower filtration units have several benefits that transform the filtration landscape and help reduce the risk of corrosion, microbiological growth, and scale. some of these benefits include: reduces under deposit corrosion, eliminates the nourishment for biological growth, and prolongs the basin's lifespan. A comprehensive inspection and cleaning are vital before starting a cooling tower, especially after a downtime. it's crucial to check for debris, sediment, and any signs of microbial growth, such as legionella, which thrives in stagnant water. systems that have been inactive, particularly during warmer months, are at higher risk for developing.

Comments are closed.