Parallel Plate Heat Exchanger

Parallel Heat Exchangers Explained Engineerexcel Parallel plate heat exchangers may be finned or corrugated and may be used in single pass ( fig. 3.30a) or multipass ( fig. 3.30b) modes of operation. flow passages associated with compact heat exchangers are typically small ( dh 5 mm), and the flow is usually laminar. The plate heat exchanger (phe) is a specialized design well suited to transferring heat between medium and low pressure fluids. welded, semi welded and brazed heat exchangers are used for heat exchange between high pressure fluids or where a more compact product is required. in place of a pipe passing through a chamber, there are instead two.

Parallel Plate Heat Exchanger The counter flow heat exchanger has three significant advantages over the parallel flow design. first, the more uniform temperature difference between the two fluids minimizes the thermal stresses throughout the exchanger. second, the outlet temperature of the cold fluid can approach the highest temperature of the hot fluid (the inlet temperature). 18.5 heat exchangers. Plate heat exchanger (phe) explained. Δ = Δ , Δ , is the lmtd for the case of a counter flow heat exchanger with the same inlet and outlet temperatures. the correction factor, , depends on the geometry of the heat exchanger and the inlet and outlet temperatures of the hot and cold fluid streams. in general ≤ 1, and the limiting value of 1 corresponds to a counter flow heat.

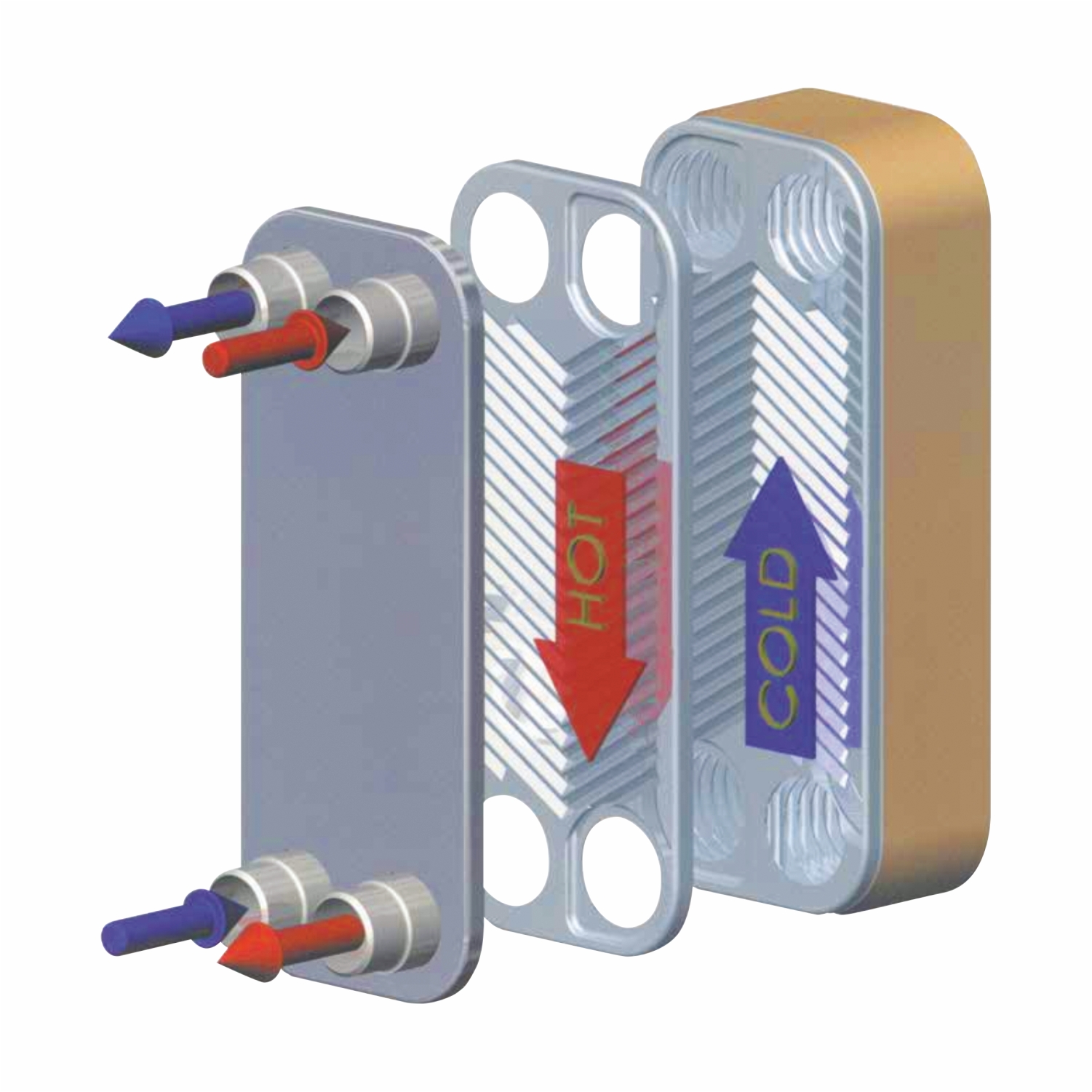

Plate Heat Exchanger Phe Explained Savree Savree Plate heat exchanger (phe) explained. Δ = Δ , Δ , is the lmtd for the case of a counter flow heat exchanger with the same inlet and outlet temperatures. the correction factor, , depends on the geometry of the heat exchanger and the inlet and outlet temperatures of the hot and cold fluid streams. in general ≤ 1, and the limiting value of 1 corresponds to a counter flow heat. Measurements are made of the heat transferred between two identical parallel plate heat exchangers under conditions of oscillating flow over a range of frequencies and amplitudes. the results are analyzed and summarized in terms of heat exchanger effectiveness, the ratio of the actual heat transfer rate to the maximum possible heat transfer rate. Here’s a more detailed explanation of the process: ♦ fluid flow: the two fluids, typically hot and cold, enter the heat exchanger through separate inlet ports. these fluids flow on opposite sides of the plates, creating a counterflow or parallel flow arrangement. ♦ plate design: the plates in a plate heat exchanger design have.

Working Principle Of Plate Heat Exchanger Linquip Measurements are made of the heat transferred between two identical parallel plate heat exchangers under conditions of oscillating flow over a range of frequencies and amplitudes. the results are analyzed and summarized in terms of heat exchanger effectiveness, the ratio of the actual heat transfer rate to the maximum possible heat transfer rate. Here’s a more detailed explanation of the process: ♦ fluid flow: the two fluids, typically hot and cold, enter the heat exchanger through separate inlet ports. these fluids flow on opposite sides of the plates, creating a counterflow or parallel flow arrangement. ♦ plate design: the plates in a plate heat exchanger design have.

Plate Heat Exchangers Saphex Sheffield Uk

Comments are closed.