Pin On Engine

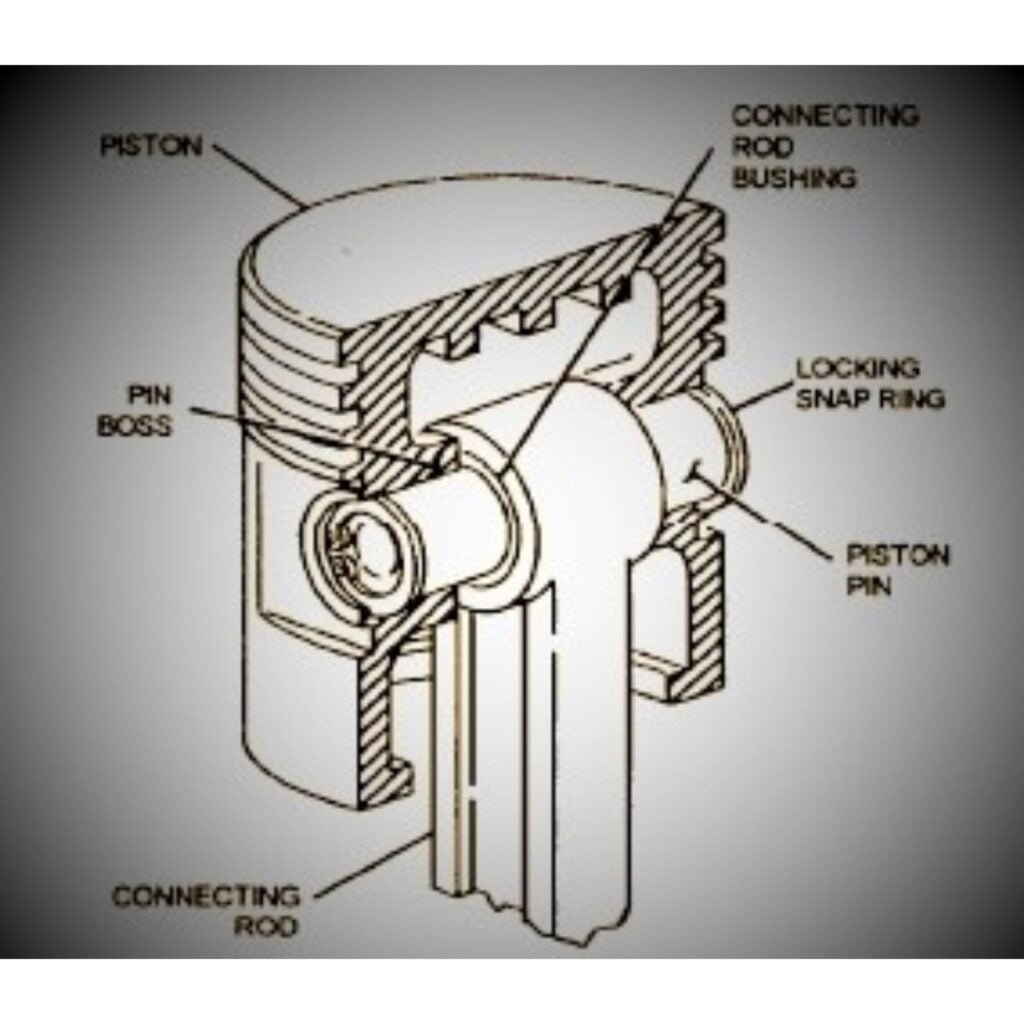

Gudgeon Pin Piston Pin Types Working Function Diagram Use a high quality oil that is recommended by the vehicle’s manufacturer. use an oil additive: oil additives can help reduce friction and wear, which can help quiet wrist pin noise. look for an additive that is designed specifically for reducing engine noise. check the engine bearings: if the connecting rod or crankshaft bearings are worn. In internal combustion engines, the gudgeon pin (english, wrist pin or piston pin us english) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves. [1] in very early engine designs, including those driven by steam, and many very large stationary or marine engines, the gudgeon.

Pin On Engines вђ Artofit Wrist pin oiling styles. single forced pin oiler – a drilled oil channel from the back of the oil ring groove to the pin bore on each side. double forced pin oiler – two oil channels from the back of the oil ring groove to the pin bore on each side. double broach oilers – two broaches on the pin bore that allow oil to lubricate the pin on. A thorough physical inspection of the engine components can reveal additional clues about piston wrist pin noise indicators. inspect the cylinder walls for scoring or other signs of wear, as this can indicate issues with the piston or wrist pin. bring each piston to top dead center and rock it up down and side to side to check for excessive. The pin is located in the internal combustion engine, passing through the piston skirt. a bent wrist pin will cause a noise to happen. typically, there are two types of wrist pins: the (semi ) floating pin and the anchored or fixed pin. with the support of a bushing, the fixed wrist pin hinges within the end of the connecting rod. These wrist pins really need 0.001 to 0.0012 inch of clearance to ensure proper lubrication. always have your machine shop check this, especially on new connecting rods, and open the clearance if they measure less than 0.001 inch. an engine builder friend recently experienced piston damage on a 750 horsepower, carefully built small block chevy.

Remove Stubborn Dowel Pins From Your Engine Easy Youtube The pin is located in the internal combustion engine, passing through the piston skirt. a bent wrist pin will cause a noise to happen. typically, there are two types of wrist pins: the (semi ) floating pin and the anchored or fixed pin. with the support of a bushing, the fixed wrist pin hinges within the end of the connecting rod. These wrist pins really need 0.001 to 0.0012 inch of clearance to ensure proper lubrication. always have your machine shop check this, especially on new connecting rods, and open the clearance if they measure less than 0.001 inch. an engine builder friend recently experienced piston damage on a 750 horsepower, carefully built small block chevy. 1. stationary. the stationary pin is secured to the piston on the boss, and the connecting rod slides on the pin. since all movement is made by the connecting rod, can occur uneven wear on the contact surfaces in this type of installation. due to this, the use of this type of pin is not typical in diesel engines. 2. The wrist pin has an incredibly vital job, shuttling over 11,000 pounds of force up and down the bore. choosing the right pin for the application is critical. you would be hard pressed to find a component in a performance or race engine that is less glamorous than the modest wrist pin. but consider how much abuse this component must withstand.

Pin On Engines The Lifeblood Of A Gearhead 1. stationary. the stationary pin is secured to the piston on the boss, and the connecting rod slides on the pin. since all movement is made by the connecting rod, can occur uneven wear on the contact surfaces in this type of installation. due to this, the use of this type of pin is not typical in diesel engines. 2. The wrist pin has an incredibly vital job, shuttling over 11,000 pounds of force up and down the bore. choosing the right pin for the application is critical. you would be hard pressed to find a component in a performance or race engine that is less glamorous than the modest wrist pin. but consider how much abuse this component must withstand.

Pin On Engine

Comments are closed.