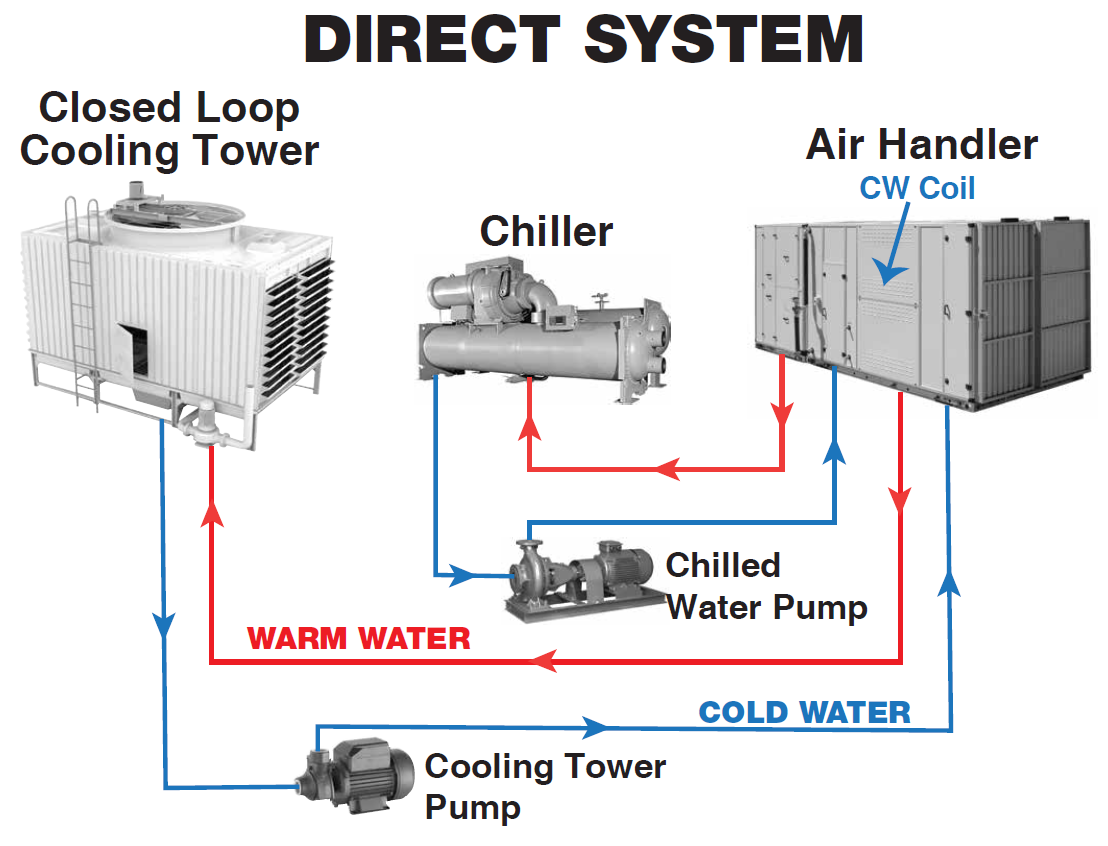

Water Cooling Tower System Diagram

How Do Cooling Towers Work Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

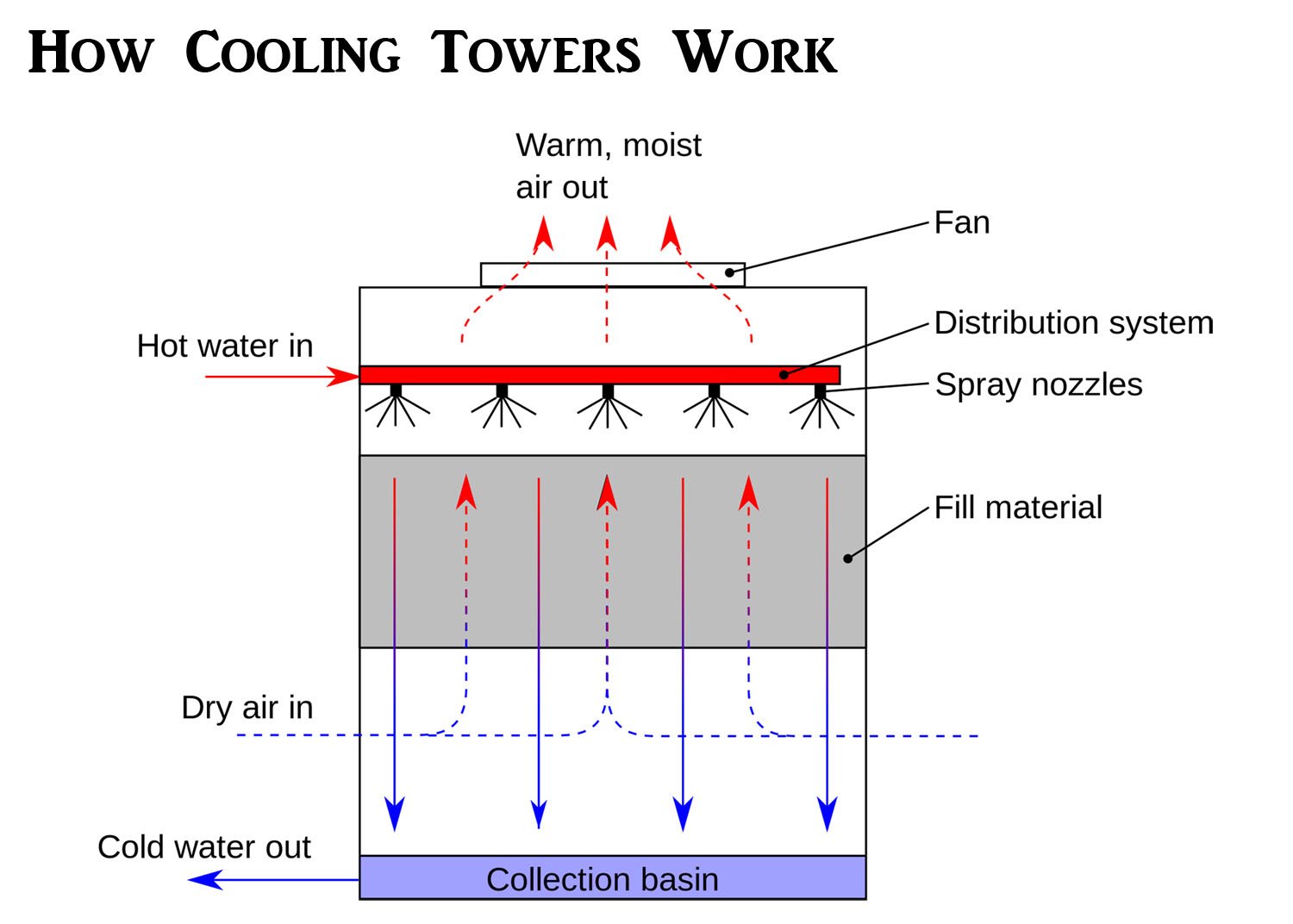

Diagram Of Wet Cooling Tower Mechanical Draft Download Scientific The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. 1.5 common cooling water system problems. water related problems can cause system downtime, loss of equipment efficiency, the need for capital replacement of equipment, and can increase the risk of disease from pathogenic microorganisms. an open recirculating cooling tower system has a greater potential for these problems than. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. A cooling tower flow diagram is a visual representation of the flow of water and air in a cooling tower system. it provides a clear understanding of how the cooling tower operates and helps in identifying potential issues or inefficiencies in the system. there are several benefits of using a cooling tower flow diagram. 1. improved maintenance:.

Cooling Towers Explained How Does A Cooling Tower Work Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. A cooling tower flow diagram is a visual representation of the flow of water and air in a cooling tower system. it provides a clear understanding of how the cooling tower operates and helps in identifying potential issues or inefficiencies in the system. there are several benefits of using a cooling tower flow diagram. 1. improved maintenance:. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. The cold air drawn in through the bottom hits the exchange surface, cooling down the hot water which then drops into the basin at the bottom of the cooling tower. this water is then funnelled back into the industrial system industrial process from where it came and the whole cycle begins again. it is estimated that around 2% of the water which.

How Cooling Towers Work W Diagram Pictures Principles 2018 The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. The cold air drawn in through the bottom hits the exchange surface, cooling down the hot water which then drops into the basin at the bottom of the cooling tower. this water is then funnelled back into the industrial system industrial process from where it came and the whole cycle begins again. it is estimated that around 2% of the water which.

Process Tech Oper Academy Hyperbolic Cooling Towers

Comments are closed.