What Is A 6 Axis Robot

6 Axis Ya Yamaha Robotics Another part of the 6 axis robot is the controller. a 6 axis robot controller is an electrical cabinet that houses all the main electrical components that are needed to drive the servo motors for each axis. these cabinets have a few different main components. – they have a disconnect switch that allows for lockout tagout functions. A six axis robot, as the name suggests, has six axes. each axis is a joint that allows the robot to move in a different way (rotate, twist, etc.). these different movements are referred to as degrees of freedom. six axis robots are a form of articulated robots that can perform an extensive range of applications, thanks to their flexibility.

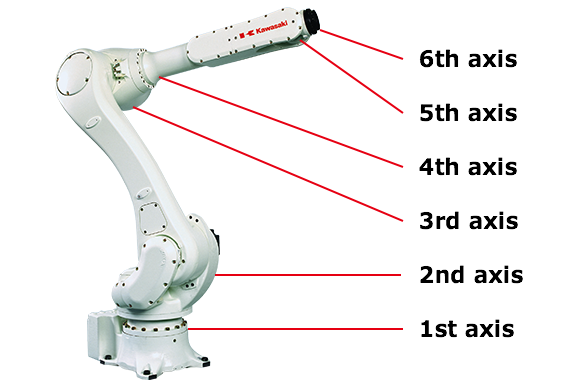

Robot Axes Drive Safety And Power Architectures Axis 6. this is the wrist of the robot arm. it is responsible for a twisting motion, allowing it to rotate freely in a circular motion, both to position end effectors and to manipulate parts. it is usually capable of more than a 360 degree rotation in either a clockwise or counterclockwise direction. A 6 axis robot arm has six joints that correspond to the six degrees of freedom required for precise movement. the "axes" refer to the joints and how the arm can rotate, bend, or move in different directions, much like a human arm. let’s break down the key components:. Axis six axis six is the wrist of an industrial robot. this axis is responsible for the complete 360 degree rotations of the wrist. the sixth axis gives industrial robots the ability to change a part’s orientation in the x, y, and z planes with roll, pitch, and yaw movements. there are a wide variety of six axis robots. From the bottom axis to the top of the robot tool, in this short 7 minute video you will learn what each axis does. this is a foundation video that shows the.

Six Axis Robots Applications Benefits And Cost Analysis Howtorobot Axis six axis six is the wrist of an industrial robot. this axis is responsible for the complete 360 degree rotations of the wrist. the sixth axis gives industrial robots the ability to change a part’s orientation in the x, y, and z planes with roll, pitch, and yaw movements. there are a wide variety of six axis robots. From the bottom axis to the top of the robot tool, in this short 7 minute video you will learn what each axis does. this is a foundation video that shows the. 2nd axis: this axis enables the rotation of lower robot arms to extend the rest of the arm above it forward or backward. this axis is referred to as j2 for fanuc r 2000ib. 3rd axis: the 3rd axis moderates the vertical reach of the six axis robot. the upper arm is raised or lowered with the servomotor located at this axis. Axis 6 this is the wrist of the robot arm, responsible for a twisting motion, allowing it to rotate freely in a circular motion. applications for six axis robots part picking and handling while most robots can handle simple part picking, a six axis robot can perform more complicated tasks that require a higher level of dexterity.

Six Axis Robots Applications Benefits And Cost Analysis Howtorobot 2nd axis: this axis enables the rotation of lower robot arms to extend the rest of the arm above it forward or backward. this axis is referred to as j2 for fanuc r 2000ib. 3rd axis: the 3rd axis moderates the vertical reach of the six axis robot. the upper arm is raised or lowered with the servomotor located at this axis. Axis 6 this is the wrist of the robot arm, responsible for a twisting motion, allowing it to rotate freely in a circular motion. applications for six axis robots part picking and handling while most robots can handle simple part picking, a six axis robot can perform more complicated tasks that require a higher level of dexterity.

Comments are closed.