What Is Ferrite Cementite Pearlite Martensite Austenite

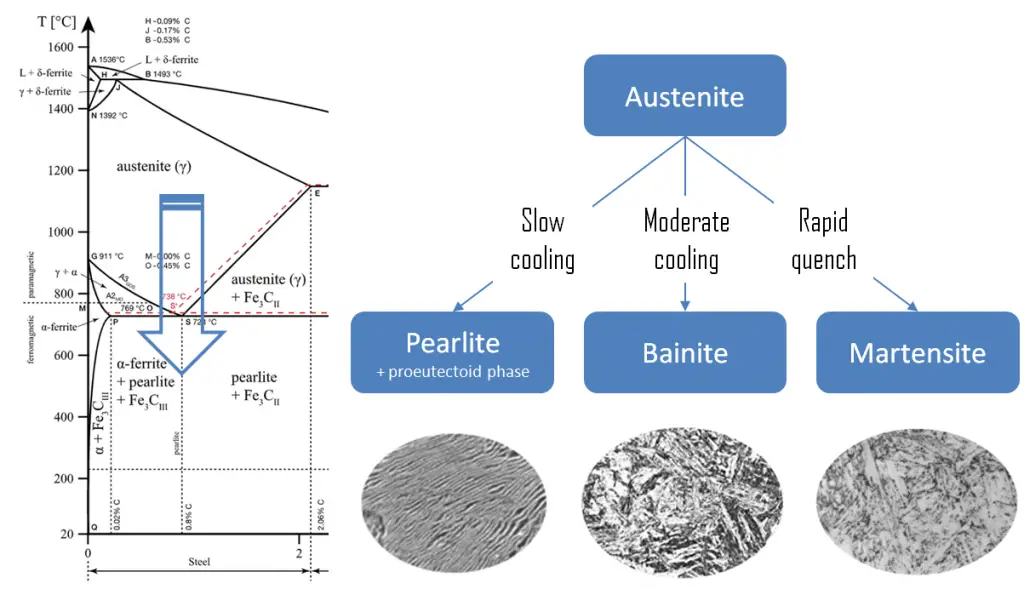

What Is Ferrite Cementite Pearlite Martensite Austenite 3. pearlite: pearlite is the name given to a mixture of about 87.5 percent ferrite and 12.5 percent cementite. it consists of alternate layers of ferrite and cementite in steel. under high magnification the ferrite and cementite can be seen to be arranged in alternate laminations or plates. Martensite is formed in steels when the cooling rate from austenite is sufficiently fast. it is a very hard constituent, due to the carbon which is trapped in solid solution. unlike decomposition to ferrite and pearlite, the transformation to martensite does not involve atom diffusion, but rather occurs by a sudden diffusionless shear process.

What Is Ferrite Cementite Pearlite Martensite Austenite Mechtech Guru The atomic mechanism of bainite is similar to that of martensite (fig. 33). plates of bainite form without any diffusion, but shortly after transformation, the carbon partitions into the residual austenite and precipitates as cementite between the ferrite platelets this is the structure of upper bainite (fig. 34). 6. pearlite. pearlite is formed when an austenitic phase of an iron carbon alloy is cooled slowly. pearlite is formed of alternating layers of ferrite and cementite, which gives pearlite significant toughness and strength. 7. martensite. martensite is created by rapidly cooling a face centered cubic austenite phase. Austenite microstructure at two different temperatures. as austenite cools, the carbon diffuses out of the austenite and forms carbon rich iron carbide (cementite) and leaves behind carbon poor ferrite. depending on alloy composition, a layering of ferrite and cementite, called pearlite, may form. Martensite has a lower density than austenite, so that the martensitic transformation results in a relative change of volume. [4] of considerably greater importance than the volume change is the shear strain, which has a magnitude of about 0.26 and which determines the shape of the plates of martensite. [5].

What Is Pearlite Definition Material Properties Austenite microstructure at two different temperatures. as austenite cools, the carbon diffuses out of the austenite and forms carbon rich iron carbide (cementite) and leaves behind carbon poor ferrite. depending on alloy composition, a layering of ferrite and cementite, called pearlite, may form. Martensite has a lower density than austenite, so that the martensitic transformation results in a relative change of volume. [4] of considerably greater importance than the volume change is the shear strain, which has a magnitude of about 0.26 and which determines the shape of the plates of martensite. [5]. 1. austenite 2. ferrite 3. cementite 4. pearlite. 1 austenite. austenite is a solid solution of free carbon (ferrite) and iron in gamma iron. on heating the steel, after upper critical temperature, the formation of structure completes into austenite which is hard, ductile and non magnetic. it is able to dissolve large amount of carbon. Cementite forms directly from the melt in the case of white cast iron. in carbon steel, cementite precipitates from austenite as austenite transforms to ferrite on slow cooling, or from martensite during tempering. an intimate mixture with ferrite, the other product of austenite, forms a lamellar structure called pearlite. the iron carbon phase.

Austenite Ferrite Cementite Pearlite Martensite 1. austenite 2. ferrite 3. cementite 4. pearlite. 1 austenite. austenite is a solid solution of free carbon (ferrite) and iron in gamma iron. on heating the steel, after upper critical temperature, the formation of structure completes into austenite which is hard, ductile and non magnetic. it is able to dissolve large amount of carbon. Cementite forms directly from the melt in the case of white cast iron. in carbon steel, cementite precipitates from austenite as austenite transforms to ferrite on slow cooling, or from martensite during tempering. an intimate mixture with ferrite, the other product of austenite, forms a lamellar structure called pearlite. the iron carbon phase.

Comments are closed.